Galvanising Only

Along with our partners in Shannonside Galvanising, Carlow Coatings offers the

service of collection from our workshop and delivery back to our workshop to our certified and accredited partner.

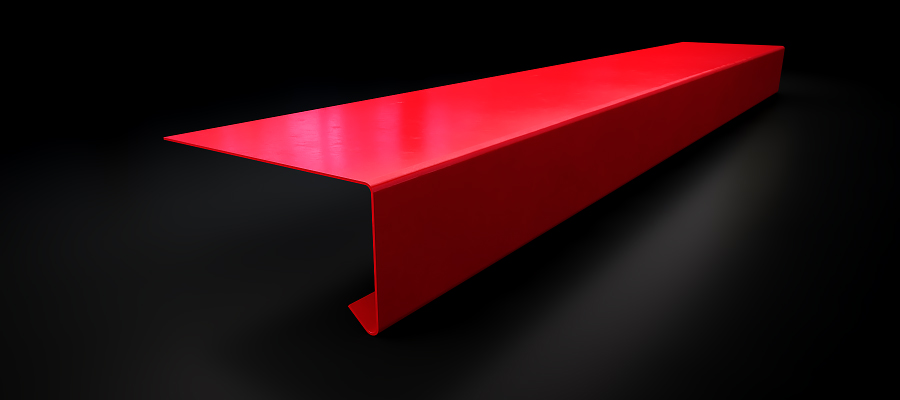

Powder Coating Over Aluminium

All aluminium works are completed in accordance with BS EN12206:1 – 2004, coated with powders from Axalta, Sherwin Williams, Interpon, Tiger, IGP, HMG, ADAPTA to your RAL requirements in our certified batch oven. Items tested using the latest in testing equipment.

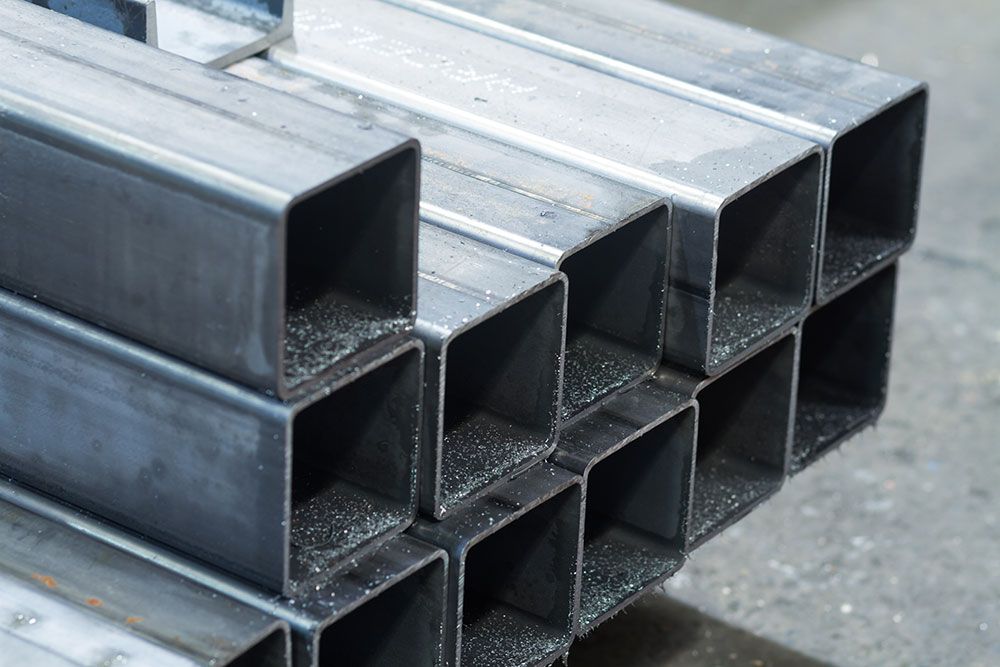

Powder Coating over Mild Steel

All mild steel items are shotblasted to SA2.5 ( ISO 8501 ) to remove all mill scale, rust, contaminants to give a clean, sound substrate for coating purposes. All mild steel parts receive a 2 part coat process from a Zinc Edge Primer and Architectural topcoat to achieve the

maximum life expectancy for Mild Steel works. Alternatively PLASCOAT can also be utilised over mild steel to achieve a high corrosion protection for harsh or extreme environments. All mild steel

projects are undertaken to achieve the class corrosion required and follows the powder specification for steelwork.

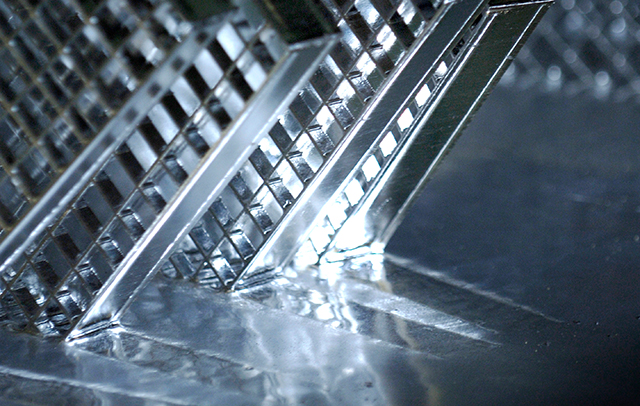

Powder Coating over Galvanised

All galvanised parts are cleaned down prior to coating to remove

any high points, drag, runs, sharp points or edges. Galv is then sweep blasted to create and etch for

the surface followed by degassing, acid etch prime and coating with an Architectural Polyester

Powder to agreed colour and finish. Zinc Edge primer is also used on certain galvanised projects

depending on the final location, shape, cut outs etc. all Galv projects are undertake to BS EN 13438 :2013